arweco

bio-compounds from Lower Saxony

Under this brand, we produce high-quality compounds based on natural fibers and biopolymers for a wide range of applications and products.

We offer a sustainable alternative for all plastic products.

Curious to find out more? Then discover more on the following pages.

What are biopolymers?

How are they used and are they biodegradable?

Biopolymers are used in various applications, including packaging materials, disposable tableware, medical devices and more. Their use helps to reduce dependence on non-renewable resources and reduce the environmental impact of conventional plastics. However, it is important to note that the environmental footprint of biopolymers also depends on factors such as cultivation, manufacturing processes and disposal. This is why we focus on sustainable production with our natural fiber filled compounds.

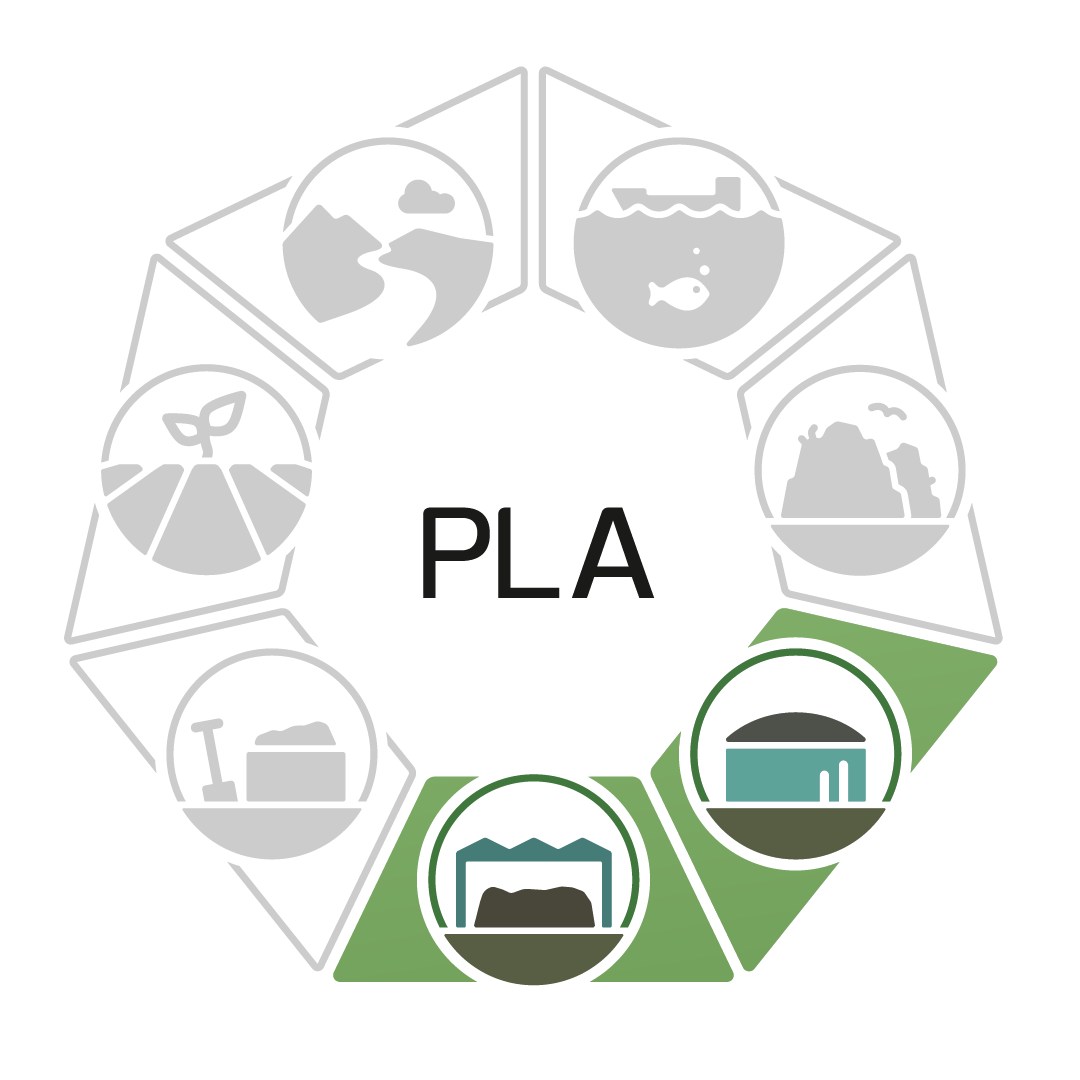

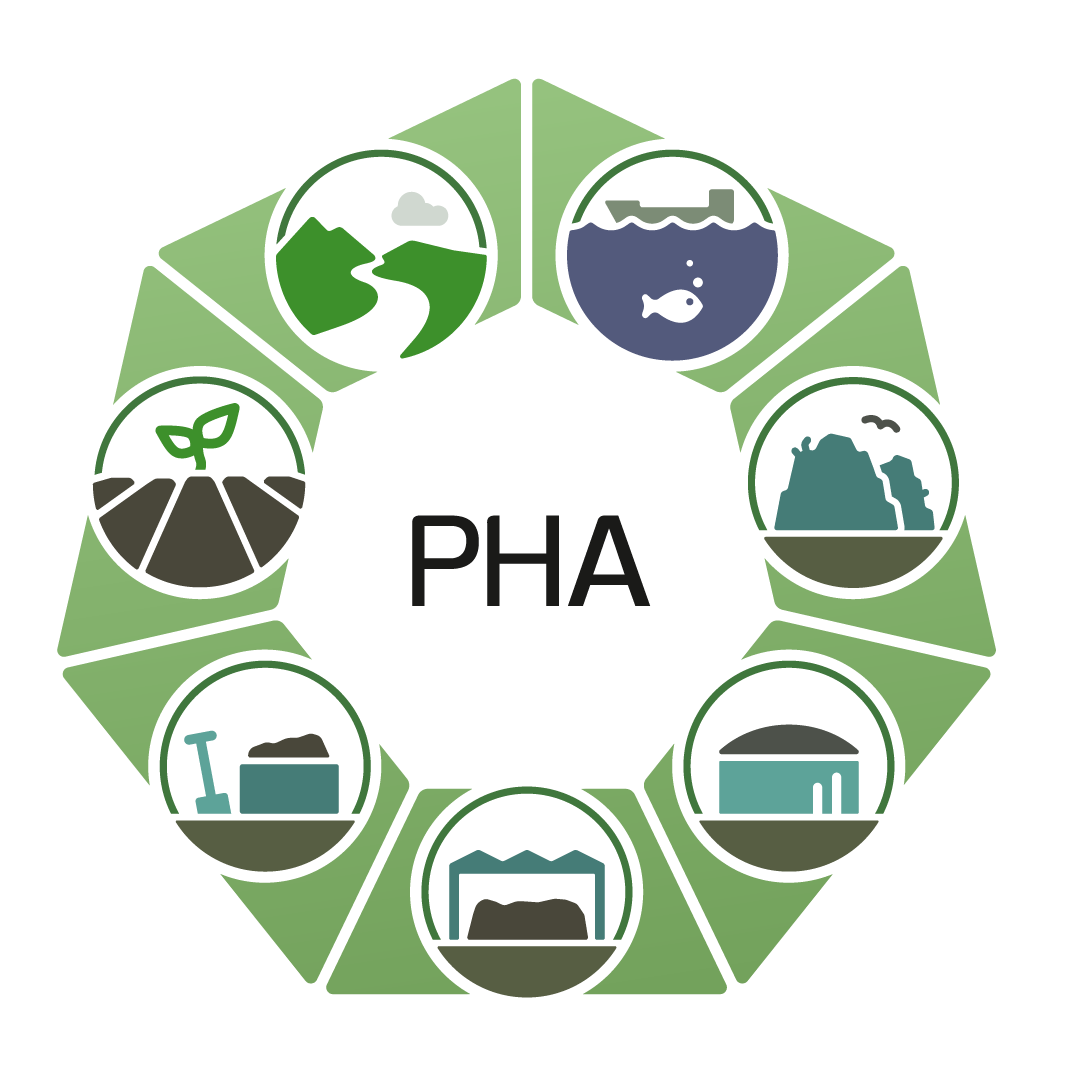

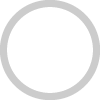

Biodegradabilty

The biodegradability of products made from biodegradable polymers is only possible if all additives and fillers used are also biodegradable. For example, dyes, platicizers and others can prevent them from biodegrading in the environment.

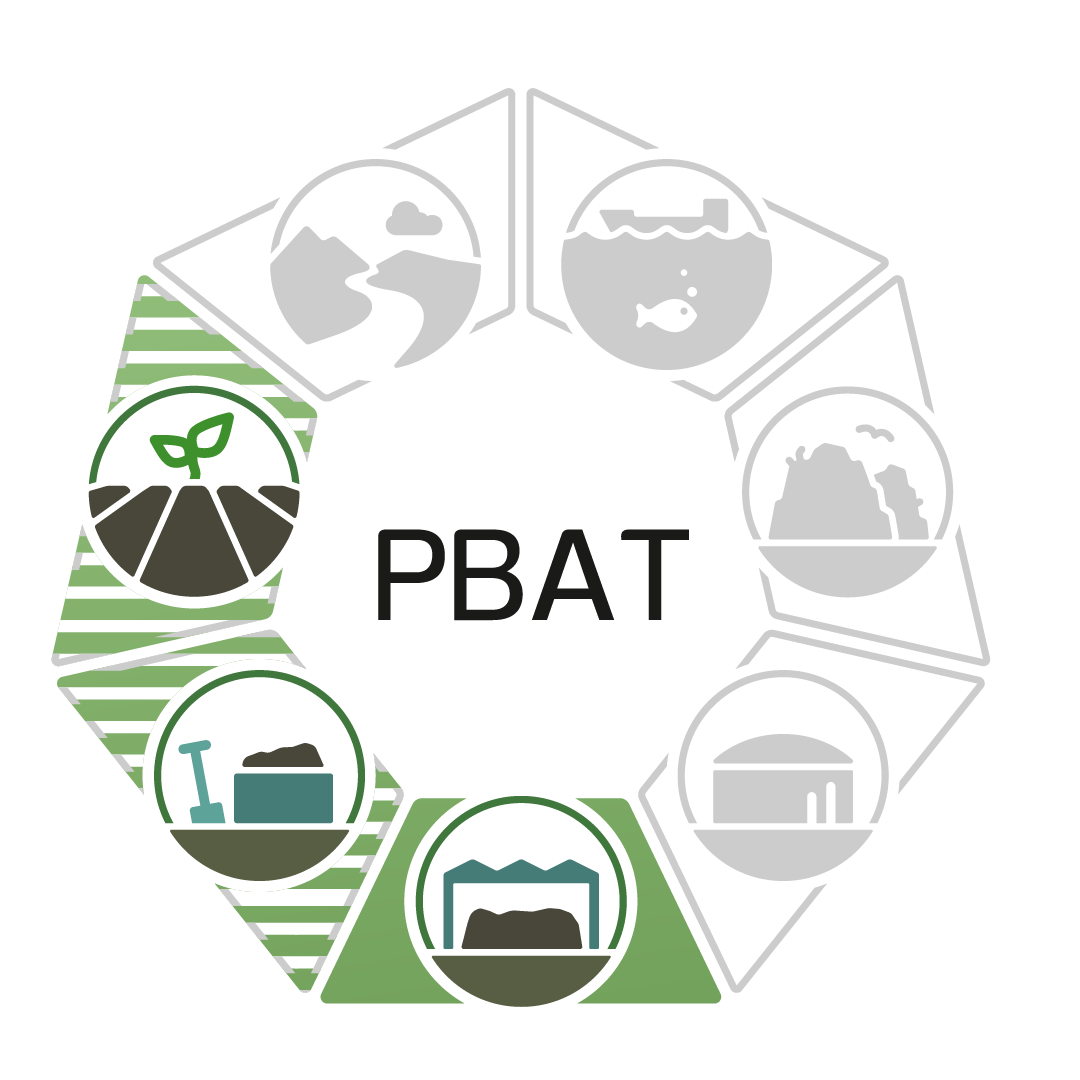

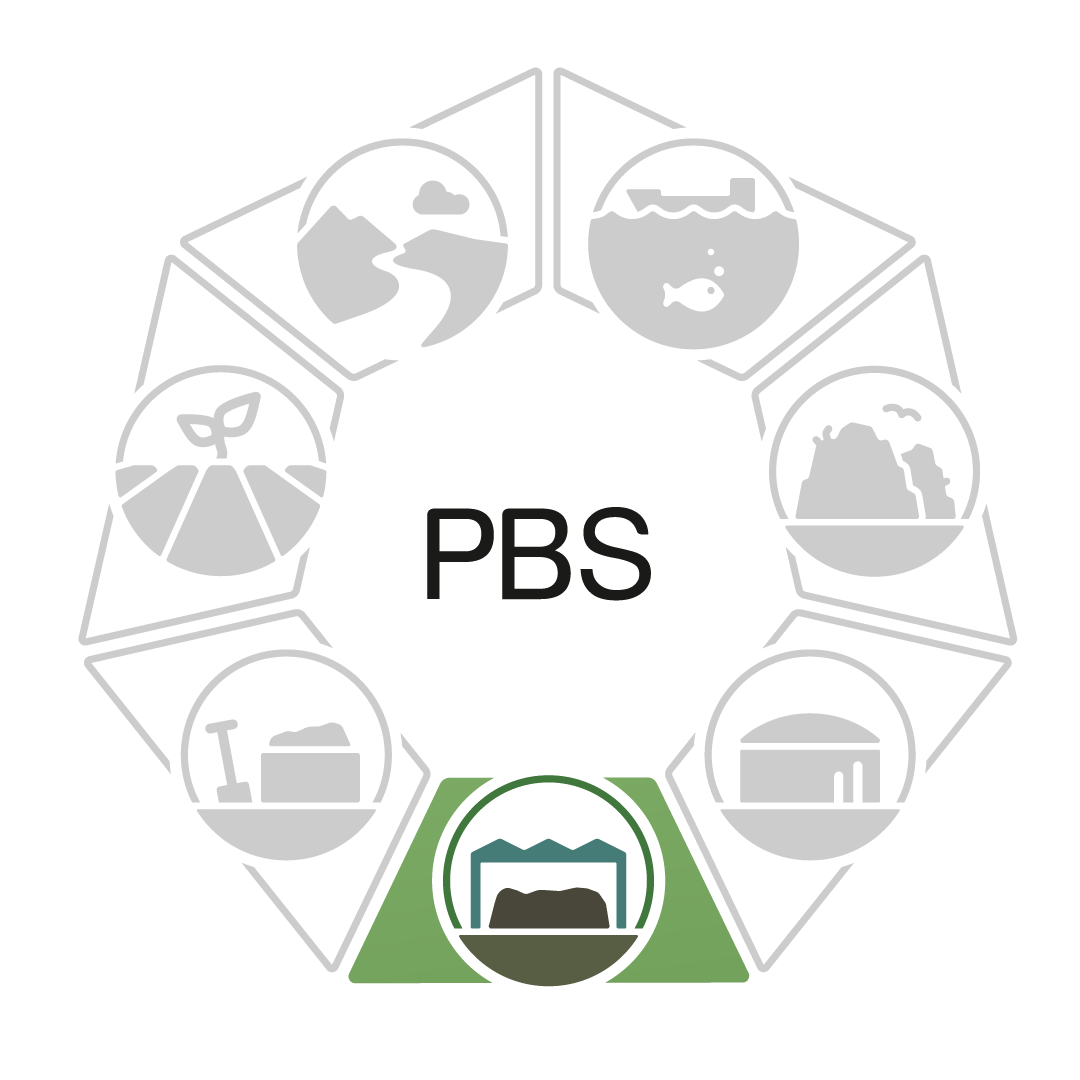

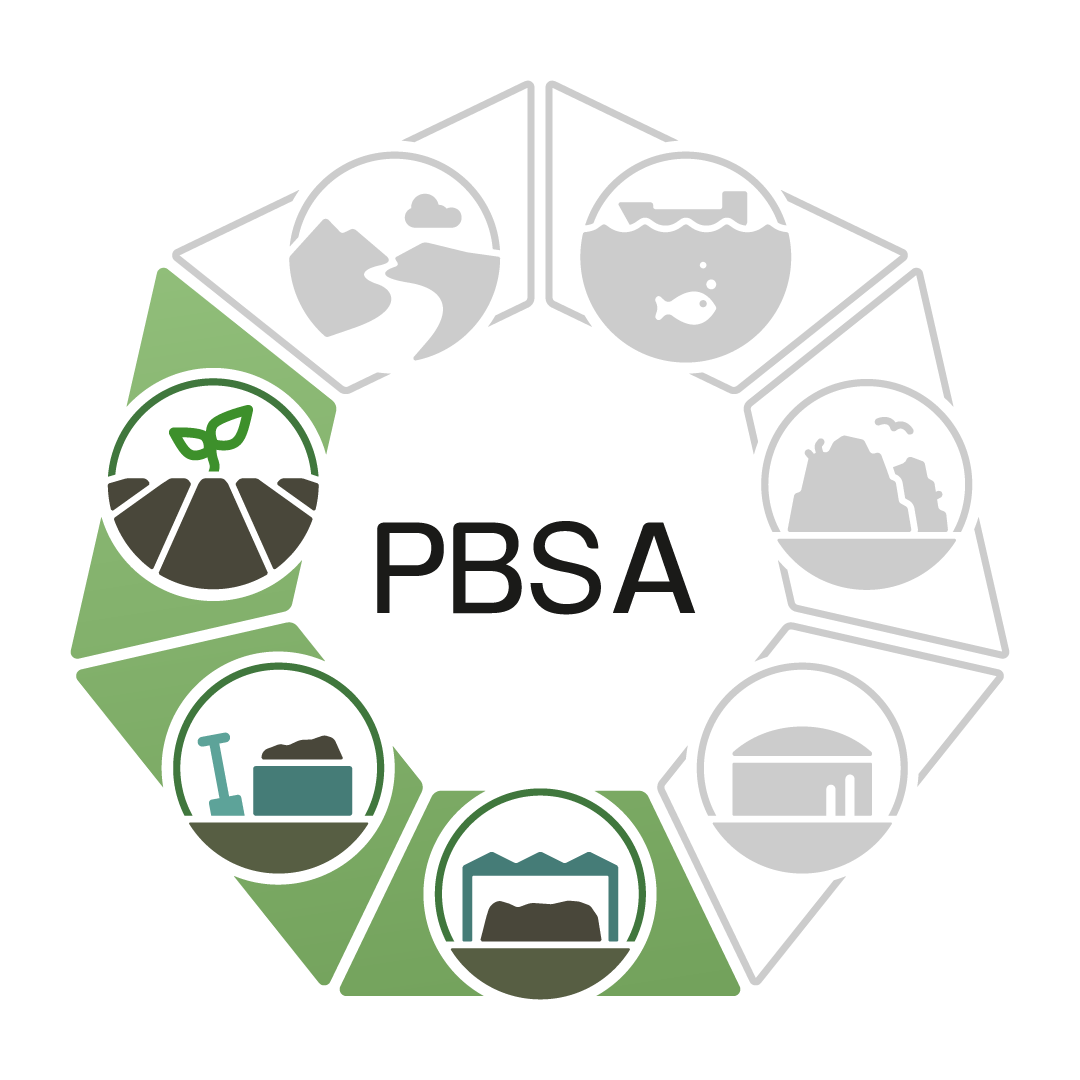

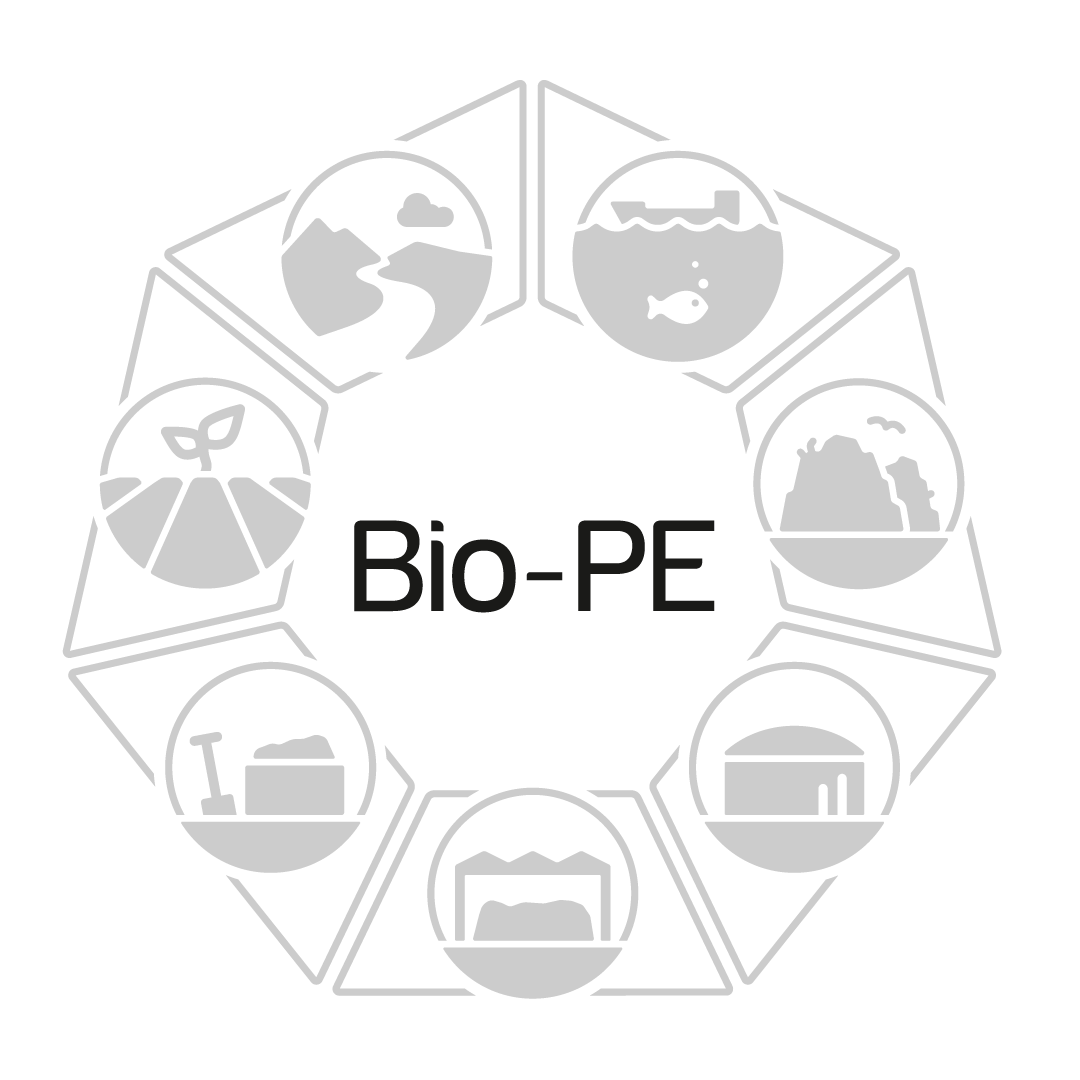

based on © nova-Institut GmbH, nova-institut.eu, 2021-11-18

Legend

proven biodegradability

proven biodegradability for certain grades

biodegradability not proven

Marine environment

Home composting

Industrial composting

Fresh water

Anaerobic digestion

Soil

Landfill

Product overview

We offer Lignura® and Otura® – bioplastic compounds with a variety of natural fibers and fiber content. Lignura® contains domestic wood fibers from PEFC-certified forestry, while Otura® uses fibers from untreated grain husks. Both compounds can be produced with different biopolymer matrices and fiber content to meet almost all requirements. The natural coloring varies depending on the natural fiber: Lignura® has a darker, woody tone, while Otura® is lighter and can be easily dyed. Mechanically, the two compounds are similar, with Otura offering a higher fiber content and good processability.

Lignura® stands for our wood fiber-based bio-compounds with different fiber contents and biopolymers.

- wood fibers

- from PEFC-certified wood

- sidestream of the sawmilling industry

- natural, woody tone

- higher stiffness

- Choice of recyclable, industrially compostable, home compostable and marine degradable biopolymers.

Otura® stands for our innovative bio-compounds based on natural fibers from oat hulls with different fiber contents and biopolymers.

- fibers from oat hulls

- organic cultivation

- sidestream of the food industry

- natural, bright color

- higher fiber content possible

- Choice of recyclable, industrially compostable, home compostable and marine degradable biopolymers.

Discover a wide range of applications!

Our biocompounds Otura® and Lignura® offer the flexibility to be used in a variety of applications. The choice of biopolymer matrix significantly influences the product design. Choose durable products with bio-based polyolefin for recycling or combustion. Our bio-based compounds also offer dishwasher resistance for repeated use. Your products, your choice!

Sustainability

We prioritize sustainability throughout the entire process chain – from the environmentally friendly selection of raw materials to innovative further processing.

Our materials are sourced from sustainable cultivation and regional sources and are processed in an environmentally friendly manner. Renewable energies play a key role in our sustainable approach. Our bio-based products are not only environmentally friendly, but also effective in offsetting CO2. Biodegradable plastics are also important for the protection of the oceans, among other things. Through their sustainable manufacturing process and low CO2 emissions, they help to minimize the environmental impact and ensure a healthier future for our oceans.

Certificates

Our products are characterized by several certifications that prove their environmental friendliness and sustainability. The home-compostable compounds are “OK compost HOME” certified, which guarantees a minimum degradation rate of 90% in 180 days. We are also PEFC-certified for sustainable forestry and our oat hulls come from controlled organic cultivation.

Our Team

Any questions about arweco Bio-Compounds? Find the right contact person here: